The world’s smallest, densest NAND Flash drive announced

The year 2010 promises significant mainstreaming of flash storage technology. Intel-Micron Flash Technologies (IMFT) – a Lehi, Utah-based joint venture of the two companies that have been sharing technology and Flash production since 2005 – has announced its 25nm NAND flash production process, making it the world’s first 25nm NAND Flash technology. This tech promises to double the storage capacity of solid-state drives (SSD) and thu of devices that use SSD drives such as smart phones, laptops, music players, etc., without increasing the size of these devices.

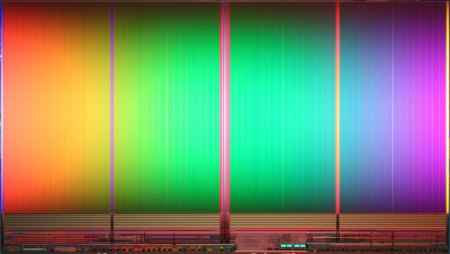

Intel-Micron 25-nanometer (nm), an 8 gigabyte (8GB) NAND Flash memory device, is the smallest, most advanced process technology in the semiconductor industry to date. It measures 167 square millimeters, which is almost the size of a CD’s middle hole and yet offers 10 times more capacity that a CD.

According to IMFT, the Flash manufacturing process is on a 12-15 month refresh cycle and thus since the company began its production in 2006 with a 50nm lithographic process, it has gone a long way. It came up with a multi-level cell (MLC) based 34nm flash chip with storage capacity of 32Gbit, storing 2 bits of data-per-cell. Last August, IMFT came up with a 3 bit-per-cell NAND flash memory technology using 34nm lithographic process, claiming a reduction of 11 per cent in flash memory size. “At 34nm, we were six to 12 months ahead of the competition, and with 25nm we believe we’ll extend that lead,” said Kilbuck, the Director of NAND market development for Micron.

This new 25nm, 8GB die is made up of many smaller 64Gbit NAND chips that hold 2 bits per memory cell and perhaps represents the fourth generation technology. With twice the capacity of the previous 34nm, we would get to see double the flash storage in the same amount of space as today. With this new NAND technology, it will be possible to build products with less than half the number of chips in comparison to what is required now with 34nm chips, leading to smaller higher density designs. For example, to build a 256 GB SSD, we just need 32 of the new 8 GB Nand flash drives, in contrast to 64. This cuts the overall cost of these SSDs and mobile products as well.

“The challenge of stepping down in lithography is to continue to provide equivalent performance… as previous products. This new 25nm NAND flash memory has the same endurance as the previous 34nm technology, with 5,000 write-erase cycles.” Troy Winslow, the Director of NAND marketing at Intel said.

These improved manufacturing processes would seem to benefit consumers of SSDs and smart phones at large when IMFT ramps up its production up to full volume by second quarter of the year 2010.