OLED burn-in mitigation: The hidden technologies protecting your display

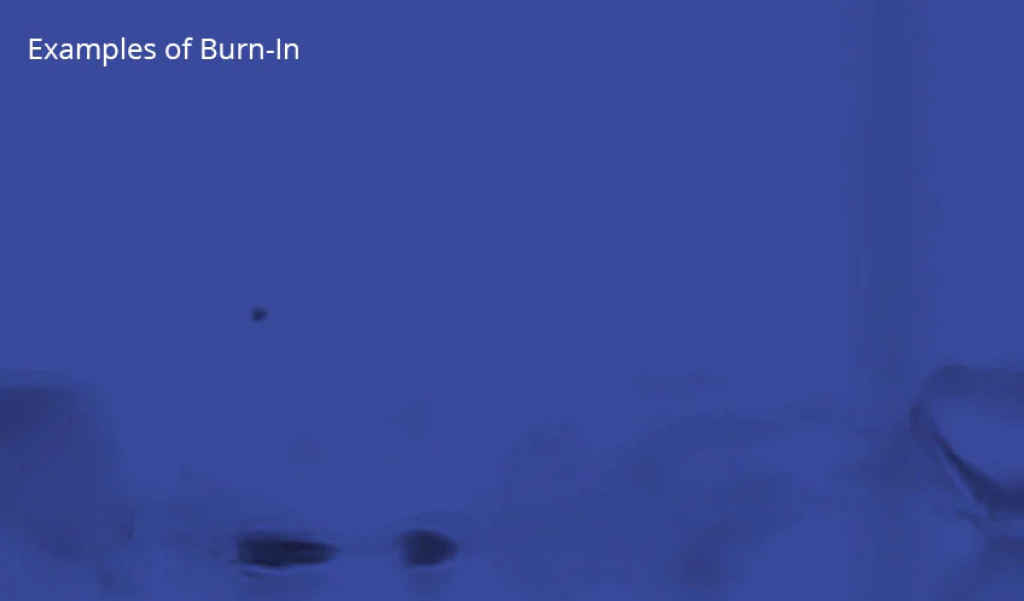

Imagine settling down to enjoy your favourite film on your stunning OLED display, only to notice a faint ghost image of your desktop taskbar hovering persistently in the corner. This phenomenon, known as burn-in, has been the Achilles’ heel of OLED technology since its inception. Despite delivering unrivalled picture quality with perfect blacks and vibrant colours, these displays have historically been plagued by the risk of permanent image retention. However, behind the scenes, engineers and materials scientists have been quietly revolutionising OLED technology with sophisticated solutions that work invisibly to protect your investment. From clever pixel-shifting algorithms to AI-powered detection systems and groundbreaking materials science, the battle against burn-in is entering a new era.

Survey

SurveyThe science behind OLED burn-in

OLED burn-in occurs when static images displayed for extended periods leave permanent marks on the screen. Unlike traditional LCD displays, each pixel in an OLED panel contains organic compounds that emit their own light when electricity passes through them. Over time, these organic materials naturally degrade, but when they emit the same level of light consistently, as happens with static images, certain pixels age faster than others.

This differential aging is particularly problematic with certain colours. Blue OLED materials tend to degrade more quickly than red or green components, making blue-heavy static elements especially concerning. The science is straightforward but vexing: the very self-emissive nature that gives OLEDs their superior picture quality also makes them vulnerable to uneven wear.

The organic compounds in OLED pixels are simply not as stable as the inorganic materials used in other display types. Under high-energy operation, prolonged exposure to electric currents leads to gradual deterioration of the materials that facilitate light emission. This fundamental characteristic has pushed manufacturers to develop increasingly sophisticated mitigation techniques.

Pixel shifting: Subtle movement for major protection

One of the most widely implemented burn-in prevention technologies is pixel shifting, which imperceptibly moves the entire image on the screen by a few pixels at regular intervals. Sony has been a pioneer in this area with their aptly named “Pixel Shift” technology, which prevents any single set of pixels from displaying static content for extended periods.

The beauty of this approach lies in its subtlety—the shifts are typically just one or two pixels in any direction, completely unnoticeable to viewers during normal use. Yet this minute movement distributes the workload across a larger set of pixels, significantly reducing the risk of uneven wear.

Google has implemented a similar approach in its Android operating system, particularly for elements like the clock on always-on displays. Their “move clock” feature subtly changes the position of persistent screen elements over time, whilst adaptive icons slightly shift position to prevent burn-in in the user interface.

The technology has evolved beyond simple back-and-forth movement. Modern pixel-shifting algorithms employ complex patterns and varying timings to ensure the most effective distribution of pixel aging whilst maintaining visual integrity.

Intelligent detection systems: Outsmarting static content

Perhaps the most fascinating developments in burn-in prevention come from intelligent systems that can identify potentially problematic screen elements and dynamically adjust them.

MSI’s OLED Care 2.0 technology exemplifies this approach with three cutting-edge features. Their taskbar detection automatically scans and identifies system taskbars in both Windows and macOS, then subtly reduces their luminance to prevent burn-in. Similarly, their multi-logo detection identifies static and contrasting logos displayed on screen and automatically dims them without compromising the overall viewing experience. The system even includes boundary detection, which identifies and adjusts the brightness at the edges between contrasting screen elements.

LG Display has developed comparable technology with its “logo luminance reduction” feature, which automatically detects static logos and reduces their brightness. Samsung takes this concept further with AI systems that analyse content and dynamically adjust pixel brightness, even predicting potential burn-in areas and compensating by slightly dimming those pixels over time.

What makes these systems remarkable is their ability to work selectively on only the problematic screen elements rather than affecting the entire display. The luminance adjustments are typically imperceptible to the naked eye and detecting them requires precise measuring instruments, yet they significantly extend panel lifespan.

Material science breakthroughs: Solving burn-in at the source

Whilst software solutions provide excellent protection, the most promising developments come from addressing burn-in at its molecular source through advanced materials science.

Researchers at the Universities of Cambridge and Manchester recently developed a new “oxadiazine” host material for blue OLED pixels, which showed an impressive 21% improvement in power efficiency whilst producing a purer blue colour. Since blue pixels are typically the first to deteriorate, enhancing their stability represents a significant advancement in overall display longevity.

LG’s “OLED EX” technology utilises deuterium compounds in the organic light-emitting devices, allowing displays to maintain high brightness whilst reducing burn-in risk. Samsung has implemented a dedicated “burn-in resistance layer” directly into their OLED structure, creating a physical barrier against the effects of static image retention.

Perhaps most promising is research from the University of Cambridge that focuses on better controlling the blue light-emitting diodes within OLED panels. By encapsulating the light emitters in insulating alkylene straps, researchers believe they could potentially eliminate burn-in issues entirely while simplifying the manufacturing process.

Another breakthrough involves thermally activated delayed fluorescence (TADF) materials, which convert less efficient triplet excitons into more efficient singlet excitons, improving both efficiency and longevity. Combined with hyperfluorescence techniques, these advances are pushing OLED panels toward 100% internal quantum efficiency.

Active panel maintenance: Refresh and recalibration

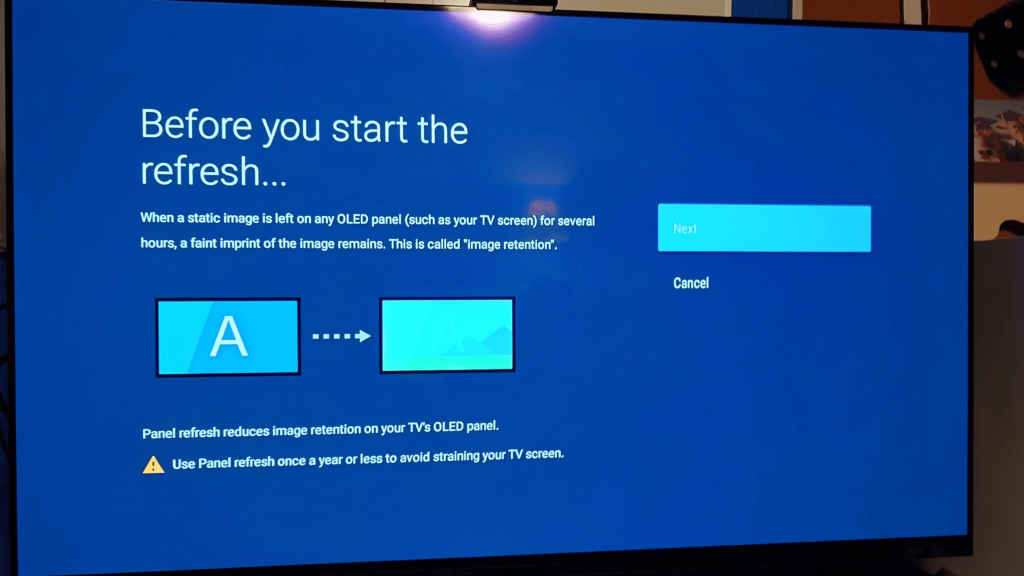

Beyond prevention, manufacturers have developed active maintenance technologies that periodically rejuvenate OLED panels.

Sony’s “Panel Refresh” function automatically runs after a predetermined number of usage hours, recalibrating the entire panel to ensure uniform brightness across all pixels. This maintenance routine effectively resets the aging clock, evening out any developing disparities before they become visible.

Heat management has emerged as another crucial factor, as elevated temperatures accelerate OLED degradation. Both Sony and LG have implemented sophisticated heat dissipation technologies to reduce overall panel temperature. Some manufacturers are even experimenting with graphene films behind panels specifically to combat heat-related burn-in.

Modern displays also incorporate automatic brightness limiters (ABL) that dynamically adjust screen brightness based on content, reducing burn-in risk during high-brightness scenes. These systems work alongside proximity sensors that can detect when users step away from the display, automatically activating protective measures when the screen is unattended.

Should you be really concerned about this?

With all these advancements, should consumers still worry about OLED burn-in in 2025? The answer is nuanced.

Burn-in remains theoretically possible but is significantly less common than in early OLED displays. Modern preventative technologies have dramatically reduced the risk for typical users who consume varied content. If you’re watching different programmes, playing diverse games, or generally using your device for mixed activities, burn-in is unlikely to affect you within the normal lifespan of your device.

That said, certain usage patterns still pose elevated risks. Displaying static content for extended periods, such as news channel logos, sports scoreboard graphics, or persistent desktop elements, can still potentially cause issues. Gamers who play the same title for hundreds of hours or business users who display static spreadsheets all day might want to exercise some caution.

Encouragingly, manufacturers now recognise these concerns, with many extending warranties to explicitly cover burn-in. This indicates growing confidence in their mitigation technologies and provides consumers with additional peace of mind.

The practical advice remains straightforward: use the built-in protection features your device offers, maintain reasonable brightness levels, vary your content when possible, and consider occasional full-screen breaks for monitors used primarily for static content. With these simple precautions and the sophisticated technologies working invisibly in the background, most users can enjoy their OLED displays without undue concern.

Ultimately, the risk of burn-in should be weighed against OLED’s undeniable picture quality advantages. The perfect blacks, superior contrast, and vibrant colours that make OLED displays so compelling continue to improve, whilst the historical drawbacks become increasingly mitigated through these hidden but hardworking technologies.

Sagar Sharma

A software engineer who happens to love testing computers and sometimes they crash. While reviving his crashed system, you can find him reading literature, manga, or watering plants. View Full Profile