Flipkart fulfillment centre secrets: What happens after you hit buy on Big Billion Days

Flipkart’s Haringhata hub blends human skill, automation, and AI

Bharath Chinamanthur emphasizes responsibility, scale, and customer obsession

Big Billion Days prep showcases Flipkart’s foresight, resilience, and logistics innovation

The first thing you notice on the drive into Haringhata is how little it suggests a logistical empire lurks here. Situated 50-km north of Kolkata’s airport, this is a town better known for dairy, poultry, and a relatively slow pace of life than back home in Mumbai. Very soon, a structure comes into view which feels wholly out-of-place and disjointed from its surroundings. It looks like an airport terminal swallowed a factory and then decided to grow a few more stories for good measure.

Survey

SurveyFlipkart’s Haringhata largest fulfillment centre – two million square feet of steel and concrete muscle – sits in this incongruous landscape like a spaceship dropped from the sky in rural Bengal. It’s the size of twelve Olympic pools, stacked across six mezzanine levels, with over five million cubic feet of storage capacity. For a company whose annual Big Billion Days sale is less an event and more national e-commerce sport, this is the stadium.

Gaining entry requires more than just a press badge. Security feels almost cinematic: three rings of perimeter checks, scanners, bag inspections. “Airport security is casual compared to this,” someone mutters beside me, and I can’t disagree. The reason becomes clear the moment you think of what’s inside, which is thousands of crores worth of inventory – phones, laptops, apparel, groceries – moving in and out with a velocity that would make a stock exchange jealous.

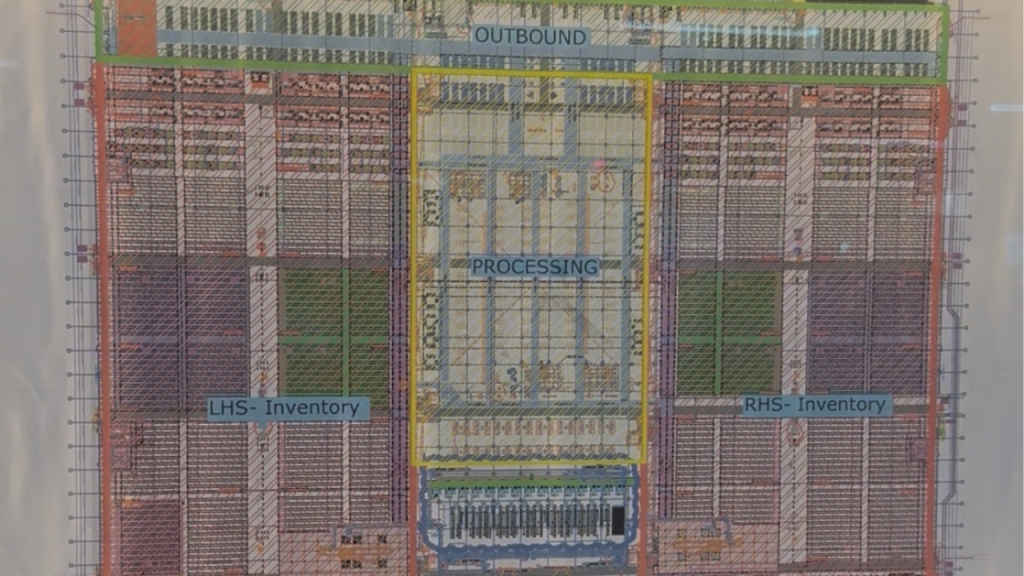

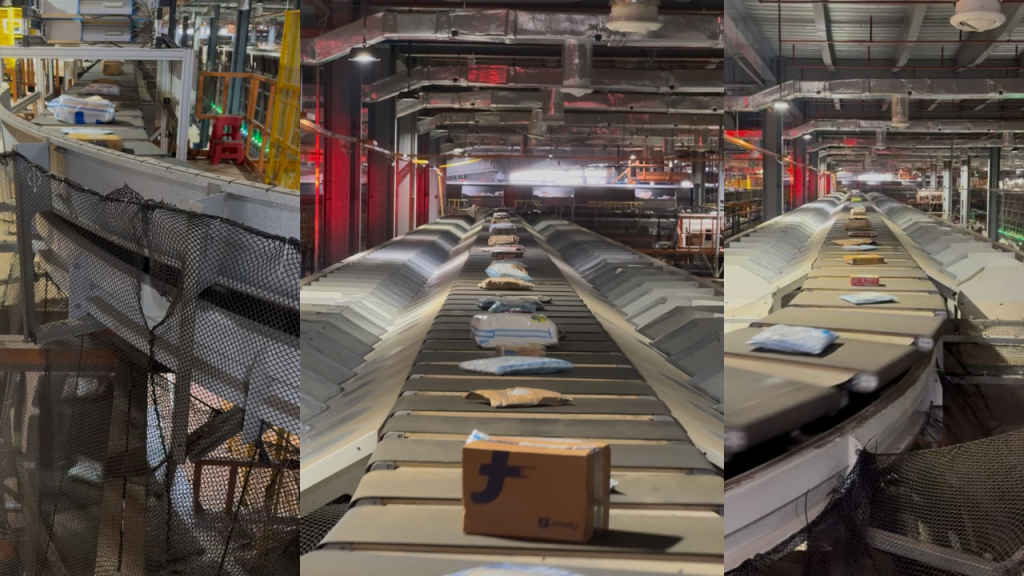

Inside, the floor plan and design layout seems deceptively simple in theory. Inbound docks on one end, outbound bays on the other. But what happens in between is anything but simple. Conveyor belts twist like roller coasters, robots glide with purpose, handheld scanners chirp in unison, and an army of workers – more like a small city in motion – orchestrates the ballet without skipping a beat. The hum is constant, but not chaotic.

“Every physical step, which is the first time we have to pick up products from the seller, bring it to our seller hub, to transport those goods from the seller hub to multiple stops in a supply chain… every physical step has a corresponding software, technology, AI, machine learning component to all of it. So almost everything is orchestrated with a high degree of sophistication,” says Bharath Chinamanthur, Flipkart’s SVP for seller experience, fulfillment, and supply chain technology, who’s trying to help me make sense of what’s happening inside Flipkart’s Haringhata fulfillment centre on any given day.

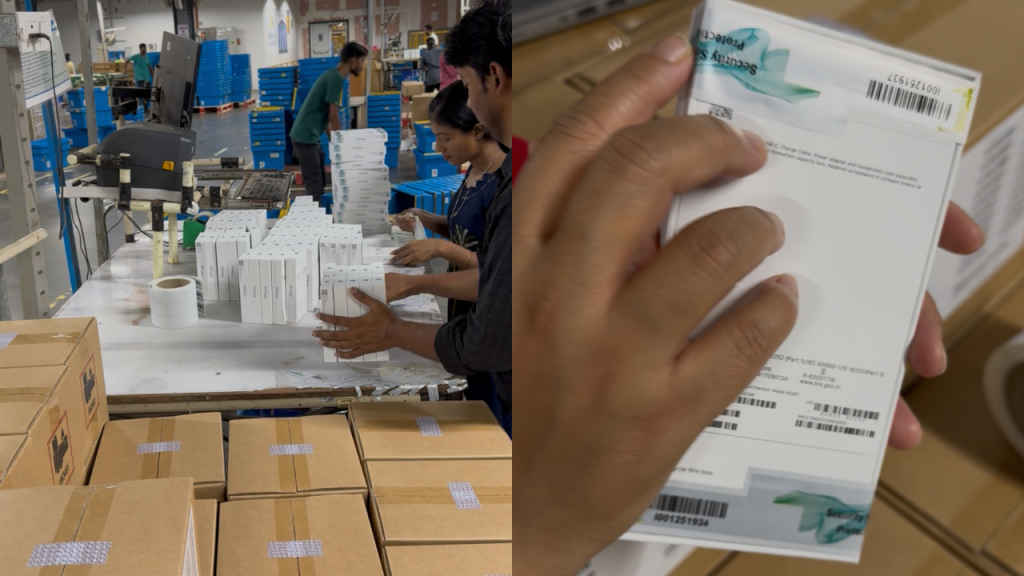

At the inbound dock, trucks unload consignments from every corner of India. As many as 25 lakh products are brought in, according to Flipkart. I watch as shipment of smartphones is cracked open and inspected – every device logged, stickered, and sealed with Flipkart’s insignia. A worker holds one phone up to the light before running it through an X-ray machine.

Also read: Content to transactions: Flipkart’s big bet on creator-fuelled commerce in India

“We are the platform. We are responsible for it all the way,” Bharath tells me. “We actually do product verification. To cut down on fraud, we use X-ray detection. So when we get a product from the seller, we inspect it… once we pick it up from a seller, the chain of custody lies with us till it ends with the customer’s hand.”

It’s a small ritual of trust, repeated thousands of times daily. Somewhere, a future customer will rip open a cardboard box and find a Flipkart security seal – never realizing the journey began here, in a warehouse hours outside Kolkata.

The choreography is relentless. New products are introduced to the system via machines that resemble laser scanners from a sci-fi film. These devices record the length, breadth, and height of each item with such precision that Flipkart knows the optimal packaging before an order is ever placed. Once logged, the data becomes permanent – the system remembers.

“Packaging is a key focus area,” Bharath says. “The LBH machine helps us accurately estimate volumetric weight, ensuring we avoid over-packaging or using incorrect package types. We know which products are best suited for soft bags, hard boxes, or other types of packaging.”

That obsession with detail is tied to a bigger goal: sustainability. Solar panels shimmer on the roof, sewage treatment plants hum at the periphery, and rainwater harvesting units tuck into corners. None of it is broadcast with fanfare – there’s no LEED certificate plaque at the entrance – but the intent is visible in steel and circuitry.

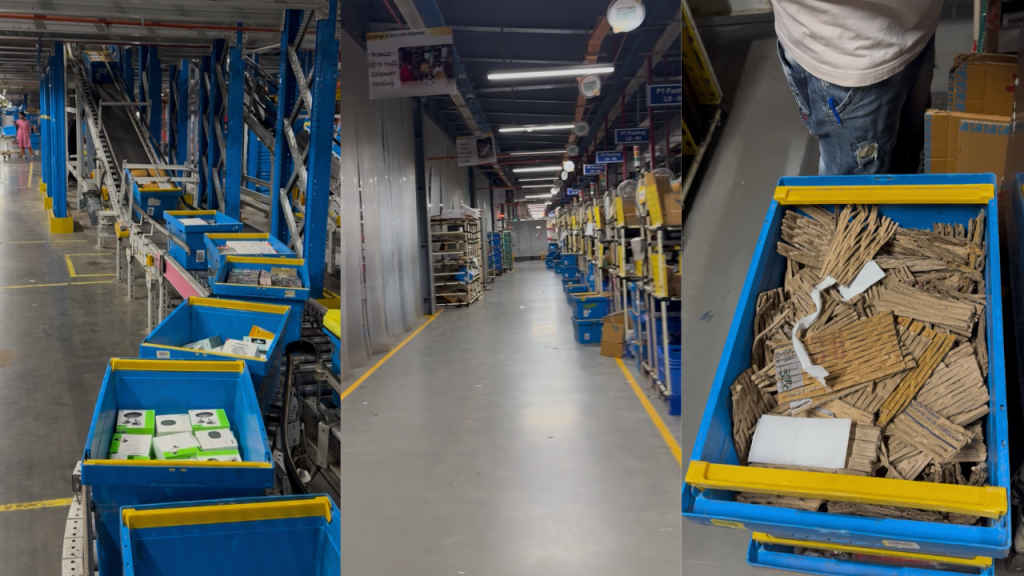

Riding the blue tote conveyor highway

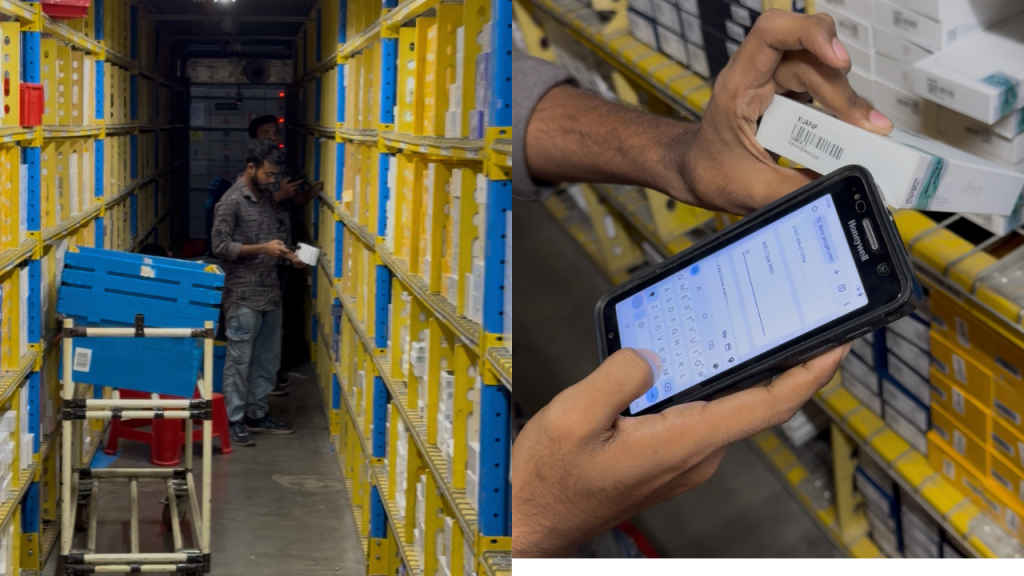

From inbound docks, goods are swallowed by what workers jokingly call the “blue tote highway.” The totes – rugged plastic bins the color of monsoon skies – carry items onto spiraling conveyors that ascend to six levels of storage. Employees follow handheld devices that tell them exactly where to deposit each piece, like a real-world video game where the stakes are customer satisfaction.

“Our forecasting models operate at three levels: one is the demand side, then there is the capacity side where we have to position inventory, and then there is the last mile side,” Bharath explains. “All three require sophistication because of the network we are operating. Humans cannot make the decision, so we have to hand it off to machines.”

In other words, when you browse Flipkart late at night and wonder if a laptop can really arrive in two days, the answer is being decided by algorithms that already nudged the machine into placing it here, in Haringhata, weeks earlier.

Not everything is automated. High-value items – smartphones, MacBooks, cameras – are whisked away into a secure cage, sealed off with layers of access control and CCTV. Inside, workers check, recheck, and sign off on inventory that may as well be gold bars for the e-commerce economy. But is it a full-proof system? For the most part, 99.9% of the time, yes.

“Sometimes it may not be the seller’s fault either. In this case, you got the wrong book – it could have been our fault too. We could have picked the wrong item. So we can’t just say the seller sent it… once it’s with us, it’s our responsibility,” Bharath admits.

It’s a refreshingly candid acknowledgement in an industry quick to blame sellers or delivery staff. The issue of wrongful deliveries is a complicated one, which is why Flipkart has started Open Box Deliveries for customers. In the Haringhata warehouse, responsibility is the gravity around which everything else orbits, which is great to see.

Up above, overlooking the fulfillment centre and warehouse floor, is a control room. It resembles a stock trading desk, only instead of ticker prices, screens display conveyor traffic in pulsating shades of green, yellow, and red. When a section of the 9-kilometre conveyor system begins to choke, operators nudge the flow elsewhere. The effect is eerily biological – as if the warehouse is a living organism, constantly self-correcting to keep the heartbeat steady.

“We have robotic pickers. We have the industry’s largest, 9 kilometre conveyor belt… and one of the largest cross-belt sorters. A lot of unique aspects about this fulfillment centre that I think, over time, we will continue to replicate all across India,” Bharath says, almost casually.

The human dimension is just as striking. On the floor, I see women working shoulder-to-shoulder with men in nearly every department – inbound verification, packaging, quality control. They wear helmets, gloves, and high-visibility vests, moving briskly between stations as automated guided vehicles trundle past, ferrying loads too heavy for human muscle. It feels more like augmentation than replacement, where machines are doing the grunt work, and humans steering those decisions.

“The most important is the human level,” Bharath stresses. “We are a very talented workforce for continuous improvement… it can’t just be technology. There can’t be one giant overseeing technology. A lot of unique innovations come from every FC.”

He’s right. The technology may be dazzling, but the quiet efficiency of the people moving through these aisles is what makes the whole apparatus function non-stop.

Packages pulled from the racks begin their final transformation at long rows of packaging stations. The pace here is intense but deliberate. Workers fold recycled cardboard, slip products into snug compartments, cushion them with paper fillers. Plastic is almost absent – a conscious choice Flipkart has made in recent years. Before sealing, each parcel is inspected once more, tagged, and released onto the conveyor system above.

That overhead track is the beating heart of the building: the cross-belt sorter. Watching it feels like standing beneath the circulatory system of a giant. Packages zip across belts, shoot down slides into sacks labeled with pin codes. The sacks are sealed, sorted, and dispatched to waiting trucks, or – in some cases – shuttled into a robotic vertical storage warehouse that holds them like a memory bank until the right truck is ready.

“At our core, Flipkart is a supply chain company. But doing this at scale, with precision and future readiness, is incredibly hard work,” Bharath tells me as we stand near the sorter. “Heroics alone cannot sustain this business. What drives Flipkart forward are reliable systems, robust processes, well-defined SOPs, and disciplined execution.”

The word “discipline” resonates. For all the conveyor wizardry, the truth is that this centre runs on routine, on thousands of repeatable actions executed without fanfare. In logistics, flair is meaningless without consistency.

Behind the scenes, AI quietly scripts much of the action. Demand forecasting, inventory placement, route optimization – all delegated to machine learning models trained on rivers of data. Humans set the goals, but the decisions happen in silico.

“Our forecasting models operate at three levels: demand side, capacity side, and the last mile,” Bharath explains again, leaning into the rhythm of the warehouse around us. “All three require sophistication because of the network we are operating. Humans cannot make the decision, so we have to hand it off to machines.”

This isn’t just number crunching. In India, even something as simple as an address can resemble a riddle. “The nature of addresses in these cities is often landmark-driven – phrases like ‘iske pichhe, uske jage gali mai’ are common,” Bharath says with a wry smile. “A significant amount of machine learning is applied to address intelligence: deciphering noise, rationalizing inconsistencies, and mapping inputs to previously successful delivery locations.”

In other words, Flipkart has built algorithms fluent in the unofficial language of Indian directions – the kind where “behind the yellow temple” or “lane inside coconut tree gate” is as good as a GPS pin.

The silent heartbeat of Flipkart’s Big Billion Days 2025

If all of this feels extreme, consider the timing of my visit – just weeks before Big Billion Days 2025. The festival sale is Flipkart’s Super Bowl, except the opponent is chaos itself. Every system here is in overdrive, stress-tested for the avalanche of orders.

“When we do BBD, we take months to prepare,” Bharath says. “We think about inventory planning, what to buy, placement, and working with brands. Sellers today get real-time dashboards of their sales performance by geography. We also provide recommendations on categories, pricing, and even gaps in selection. All of this is done in real-time.”

The math is staggering. One crore human touchpoints a day, each one a delivery attempt, a notification, a doorstep knock. And all of it is happening while sellers across the country adjust their own dials, guided by Flipkart’s data.

“All of this is done with one obsession, which is to delight the customer,” Bharath adds. “Every employee of this company gets up in the morning with customer obsession. How to satisfy a customer? How to make sure the customer is happy?”

The obsession is evident. Even as workers push through BBD prep, Flipkart is already experimenting with what comes next: Minutes. That’s the brand’s audacious promise of 10-minute delivery – a logistical moonshot built on micro-fulfillment centres and hyperlocal networks.

“Even in the Flipkart Minutes case, the product has to come from the seller into a micro-fulfillment centre. This is the shortest hop because we have to meet a 10-minute order cycle turnaround,” Bharath explains.

Quick commerce, once confined to groceries, is bleeding into other categories. Customers who expect biryani in ten minutes may soon expect a phone charger in the same time frame. Flipkart is betting that expectation will only grow.

“Customers are increasingly getting used to faster deliveries – even for larger assortments that traditionally might take two or three days. Quick commerce has played an important role in shaping this expectation,” Bharath notes.

One experiment already underway: mobile phone exchanges completed in minutes rather than days. It’s not just speed for speed’s sake – it’s recalibrating what consumers believe is possible.

But the most human piece of this puzzle isn’t in the warehouse at all. It’s on the streets, with Flipkart’s “Wishmasters.” At peak, the company hires, trains, and deploys tens of thousands of delivery staff – each one the final face of this sprawling machine.

“We recently did real-time background verification for a Wishmaster,” Bharath tells me. “Within ten minutes, if somebody wants to become a Wishmaster, they can login, create an account, and go through an instant background check. Then some training components, and they’re ready.”

Technology enables the scale, but it’s still individuals on scooters and in vans who embody Flipkart to the customer. They are the living edge of the supply chain.

What lingers after hours inside Haringhata isn’t just scale, but forward planning. The building itself was chosen with expansion in mind, its conveyor layouts designed to accommodate future belts not yet bolted in, according to Bharath Chinamanthur.

“From the top-down, we look at topology and geography – how our network needs to evolve over five or ten years,” Bharath says. “From the bottom-up, our supply chain team thinks through every detail: cross-belt sorters, conveyor layouts, expansion space. The site was selected with land for expansion in mind. It’s like having two large fulfillment centres within one structure.”

To meet this long-term vision and boost regional accessibility, Flipkart has expanded its network by 3.5 million square feet in 2025. This includes key additions like a 4.5 lakh square-foot fulfillment center in Patna, which alone is expected to create over 1,100 jobs and enable faster deliveries to more than 1,000 pin codes. They’ve also opened their first grocery fulfillment centre in Agartala, a 35,000 square-foot facility with a dispatch capacity of over 5,000 orders per day. To prepare for the festive season, they’ve launched 650 new delivery hubs in cities like Siliguri, Kundli, and Jakuhar, as well as last-mile hubs in key locations like Varanasi, Manesar, and Ranchi. Haringhata’s operations support all of these eastern and north-eastern shipments to and fro.

Walking back through the aisles of the Haringhata fulfillment centre, I keep circling back to the customer on the other side of this labyrinth. Someone tapping “Buy Now” on their phone, never pausing to wonder how that kurta or laptop arrives so fast.

“It doesn’t come intuitively to customers,” Bharath admits. “While they’re ordering from Flipkart, they’re actually connecting with a seller. But I don’t think they have an appreciation for how the product moves. For example, did this kurta really travel from Surat in two days? Maybe not. Our inventory systems plan and place inventory at the right place at the right time. Customers don’t see that sophistication.”

By the time I step back outside, blinking into the late-afternoon haze, the facility looks different. No longer just a warehouse, but something closer to a living system – half temple, half machine. A temple where the priests wear helmets, the hymns are sung by conveyor belts, and the gods are algorithms predicting demand curves.

For the customer, the process is invisible by design. You hit “Buy Now,” a parcel arrives, and life goes on. But standing here, after watching thousands of hands and terabytes of models working in tandem, it feels less like magic and more like faith upheld.

Flipkart’s Haringhata facility isn’t built to astonish journalists or impress dignitaries. It exists for one reason: to keep promises. And in the end, that’s what e-commerce really is – a vast, intricate promise machine.

Also read: Beyond BBD 2025: Inside Flipkart’s tech playbook for Indian e-commerce

Jayesh Shinde

Executive Editor at Digit. Technology journalist since Jan 2008, with stints at Indiatimes.com and PCWorld.in. Enthusiastic dad, reluctant traveler, weekend gamer, LOTR nerd, pseudo bon vivant. View Full Profile